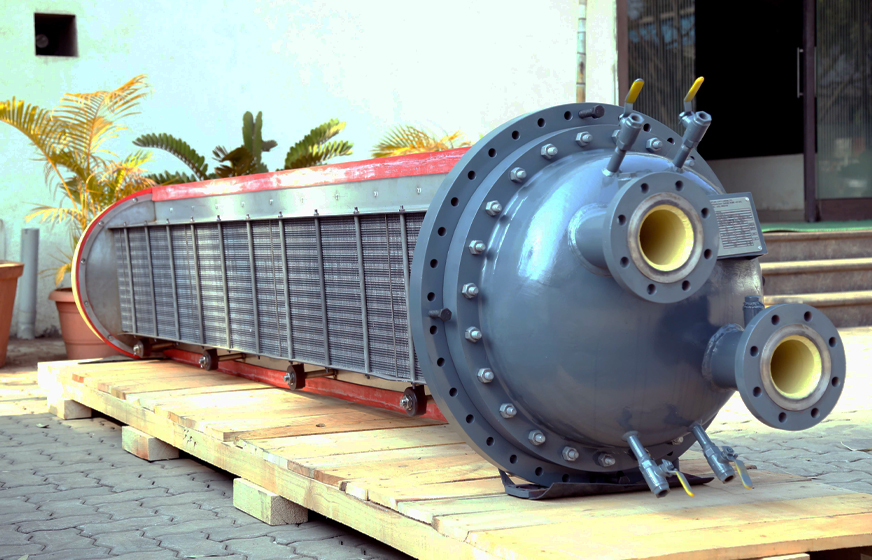

Extended Surface Heat Exchanger

Brochure

Discover the full range of our products by downloading our comprehensive brochure today!

BROCHURE.PDF

Let’s Start Work

Together

Please feel free to contact us.

Manufacturing Unit-1 & Corporate Office

Plot No. F- 131, M.I.D.C, Ambad, Nashik- 422010.

Manufacturing Unit-2

At Post Talegaon, GAT No:352, Talegaon, Indore-Rasegaon Road, TAL- Dindori, Nashik, Maharashtra 422004

Featuring increased surface area for enhanced heat transfer efficiency, they are utilized in HVAC systems, refrigeration, and industrial processes for precise temperature control.

Application

- Gas coolers (H,N,O etc)

- Process Heating & Cooling

- Waste Heat Recovery

- Driers

- Dehumidifiers

- Electric Rotating Machine Coolers

- HVAC

- Steam condensers for turbines

- Economizers

- Condensers

Specification: The finned-tubes which are incorporated in the manufacture of our Extended surface Heaters or Coolers can be produced in a wide range of sizes, configuration of tubes like longitudinal, transverse, helical fins. These finned tubed units can also be manufactured in a variety of metals or combination of metals to customers’ individual requirements.

Material

Tube Material

- Stainless Steel

- Carbon Steel

- Cupro-nickel

- Copper

- Brass

Fin Material

- Phenolic and Blue Coated Aluminum

- Aluminum

- Copper

Advantages of UHTL Extended Surface Heat Exchangers

- Low pressure drop

- Low Energy Consumption

- Low utility consumption

- Low power consumption

- Compactness

- In Built/External moisture separator

- Ease in access to tubes for Maintenance

- Flexible designs

- Maximum efficiency due to allowable cross over of outlet temp of cooling fluid

- Flexibility in locating nozzles

- Vibration less design & reduced pumping cost

Previous