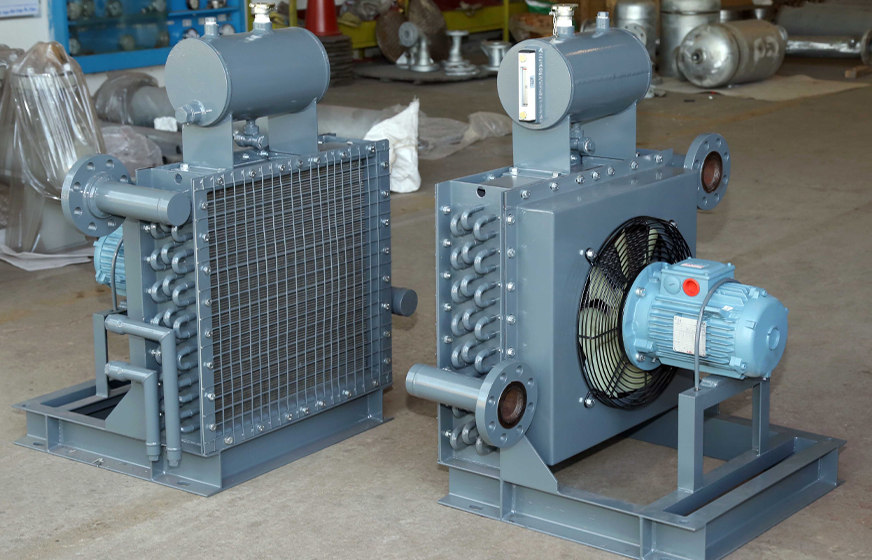

Air Cooled Heat Exchanger

Brochure

Discover the full range of our products by downloading our comprehensive brochure today!

BROCHURE.PDF

Let’s Start Work

Together

Please feel free to contact us.

Manufacturing Unit-1 & Corporate Office

Plot No. F- 131, M.I.D.C, Ambad, Nashik- 422010.

Manufacturing Unit-2

At Post Talegaon, GAT No:352, Talegaon, Indore-Rasegaon Road, TAL- Dindori, Nashik, Maharashtra 422004

Air Cooled Heat Exchangers (ACHEs) are used to transfer heat from a fluid (liquid or gas) to the ambient air. Unlike traditional water-cooled systems, air-cooled heat exchangers use air as the cooling medium, making them particularly valuable in environments where water is scarce or where water conservation is a priority.

Application

- Gas/Air Compressor Coolers

- Gas Transmission Coolers

- Engine & Generator Coolers

- Air Cooled Condensers

- Steam Condensers

- Lube Oil Cooling Systems

- Flue Gas Reactors

- CNG Booster Compressor Cooler

- Data Centre Cooling System

Advantages of UHTL Air Cooled Heat Exchangers

Advantages of UHTL Air Cooled Heat Exchangers

- Design as per TEMA, ASME Sec VIII Div-1, API 661 & PED 2014/68/EU

- Good understanding of principles of heat exchanger to design on HTRI, Bentely Autopipe-Microprotal, and PVElite

- Feasibility & Viability of design with respect to Manufacturing & Quality is verified.

- Different finned tube geometry like High-finned, low-finned, continuous-finned, stud-finned or plain tubes available.

- Analysis for Heat Transfer capacity of Fin tube for cost effective heat exchanger.

- Increase efficiency of heat exchanger by considering Heat Transfer Rate, Space requirements & Air side pressure drop.

- Selection of header with respect to service requirement.

- Fan Blade Material selection depending on the area of classification.

- Optimum Air Flow rate & Noise level for Air Cooler.

- Single bay or multi-bay design with substructures.

- F type Construction can also be manufactured.

Specification

- Our Air Cooled Heat Exchangers are designed to fulfil needs of various combinations of Pressure, Temperature, Corrosion & Fouling.

- Material: Stainless Steel, Carbon Steel, Cupro-nickel, Copper, Brass, Gun Metal, Aluminum, Aluminum Bronze, Naval Brass, Hastealloy, Inconel, Monel, Nickel etc.