Marine Heat Exchangers

Brochure

Discover the full range of our products by downloading our comprehensive brochure today!

Let’s Start Work

Together

Manufacturing Unit-1 & Corporate Office

Plot No. F- 131, M.I.D.C, Ambad, Nashik- 422010.

Manufacturing Unit-2

At Post Talegaon, GAT No:352, Talegaon, Indore-Rasegaon Road, TAL- Dindori, Nashik, Maharashtra 422004

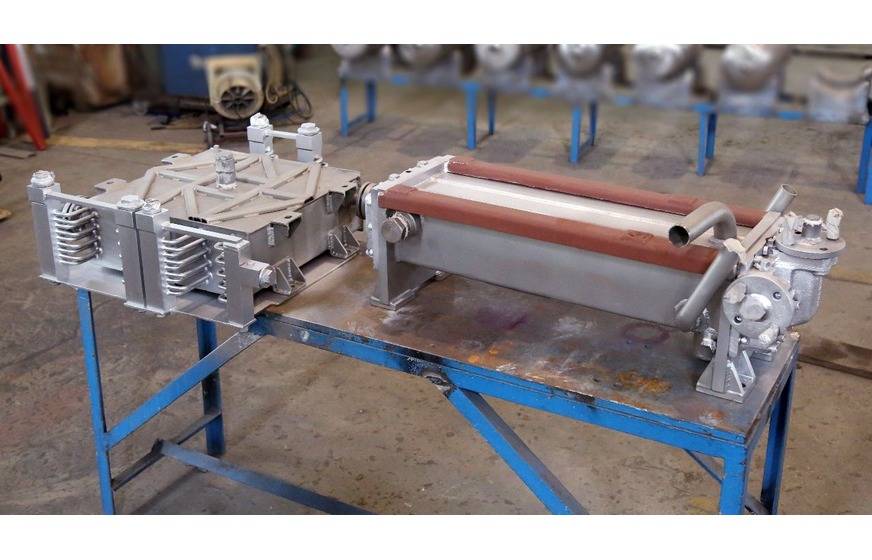

Specifically designed for maritime applications, these heat exchangers efficiently transfer heat between different fluid streams, crucial for maintaining optimal temperatures in marine engines and systems.

We are approved suppliers to the Directorate General of Quality Assurance (DGQA).

Specification

We Are Manufacturer Of The Heat Transfer Equipment as Per The TEMA (Tubular Exchanger Manufacturers Association) Standards, ASME Section VIII Div. 1, Div. 2, (Unfired Pressure Vessels), NES Standards. We Design Marine Heat Exchanger To Resist Shock Impact Load.

| Shell | Tube Sheet | Tubes | Channels / Headers / End Covers |

|---|---|---|---|

| 90/10 Cupronickel | 90/10 Cupronickel | 90/10 Cupronickel | Cupronickel |

| 70/30 Cupronickel | 70/30 Cupronickel | 70/30 Cupronickel | Nickel Aluminum Bronze |

| Carbon steel | Carbon steel | Copper | Gunmetal-Naval Grade |

| Stainless Steel | Naval Brass | Stainless Steel | Graded Cast iron |

| Stainless Steel | Al. Brass | Carbon steel & Stainless Steel | |