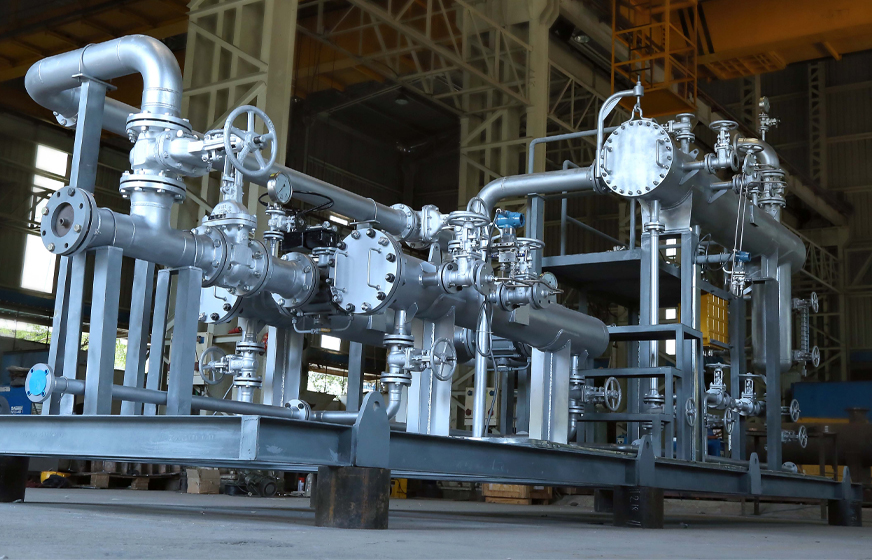

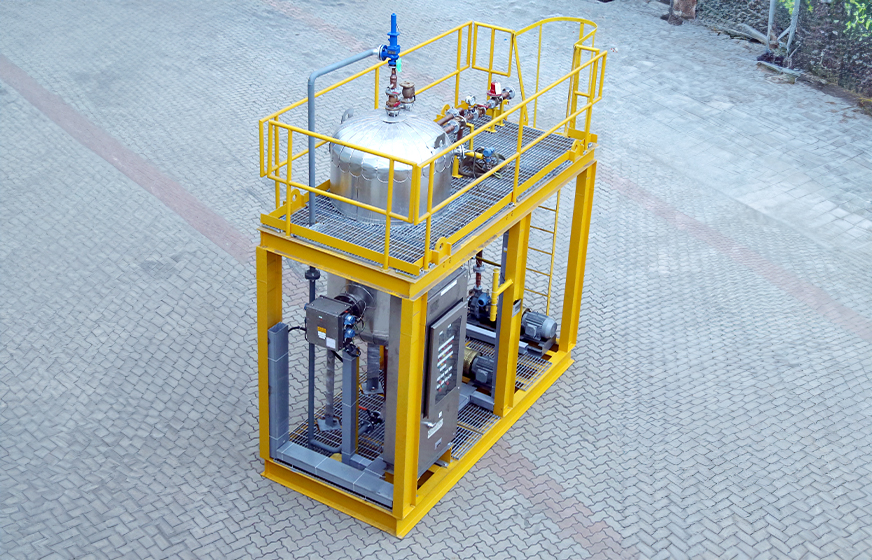

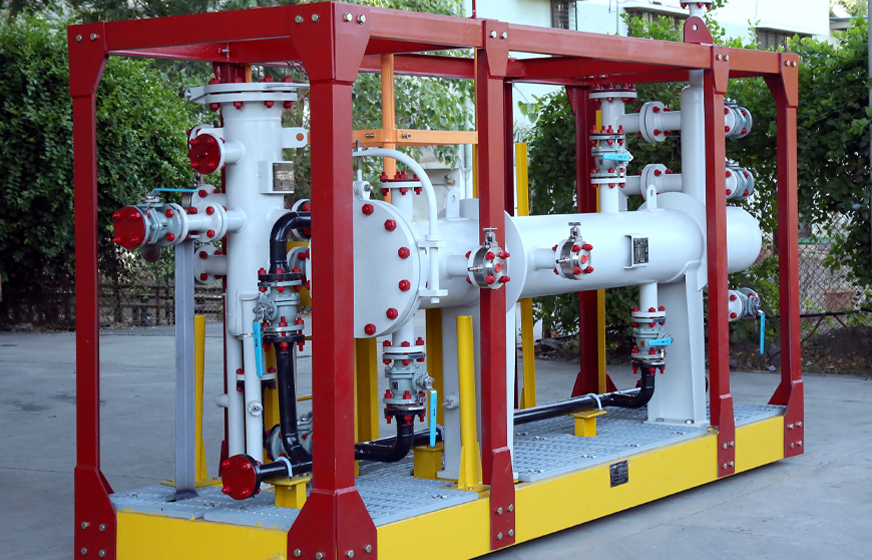

Process Flow Skid

Brochure

Discover the full range of our products by downloading our comprehensive brochure today!

BROCHURE.PDF

Let’s Start Work

Together

Please feel free to contact us.

Manufacturing Unit-1 & Corporate Office

Plot No. F- 131, M.I.D.C, Ambad, Nashik- 422010.

Manufacturing Unit-2

At Post Talegaon, GAT No:352, Talegaon, Indore-Rasegaon Road, TAL- Dindori, Nashik, Maharashtra 422004

Tailored to specific project requirements, these assemblies integrate multiple components onto a single platform, offering convenience and space-saving solutions for various industries including oil and gas, petrochemical, and pharmaceutical industry.

Application

- Filtration systems

- Water Consoles

- Lube oil consoles

- Fluid Lubrication systems

- Chemical Process Skids

- Skids for compressors

Benefits of UHTL Process Flow Skids

- Our optimized design is based on the wide range of experience which minimize space

- Our skids are designed to meet specific requirements, including sizes, materials, & configurations

- Shortest Delivery Cycle

- Expertise in selection of Instrument, pump gives customer comfort for sizing of equipment

- Single Source Accountability

- Pre-assembled, reducing installation time and costs.

Specification

- Off-site fabrication of a process system helps ensure that fabrication tasks do not lead to costly plant interruptions. A plant is also not forced to accommodate extra staff. Site-specific training and Good Manufacturing Practices (GMP) likewise become lesser concerns.

- Vessels ASME Section VIII Div. 1 & 2

- ASME U Stamp / CEPED / CRN / UK CA / CUTR

- National Board Registration

- Piping Designed to ANSI B31.1/ANSI B31.3

- Pipe Fabrication to ASME Section IX

- Structural Steel Assembly Designed to IS Standard, ASCE

Previous

Next