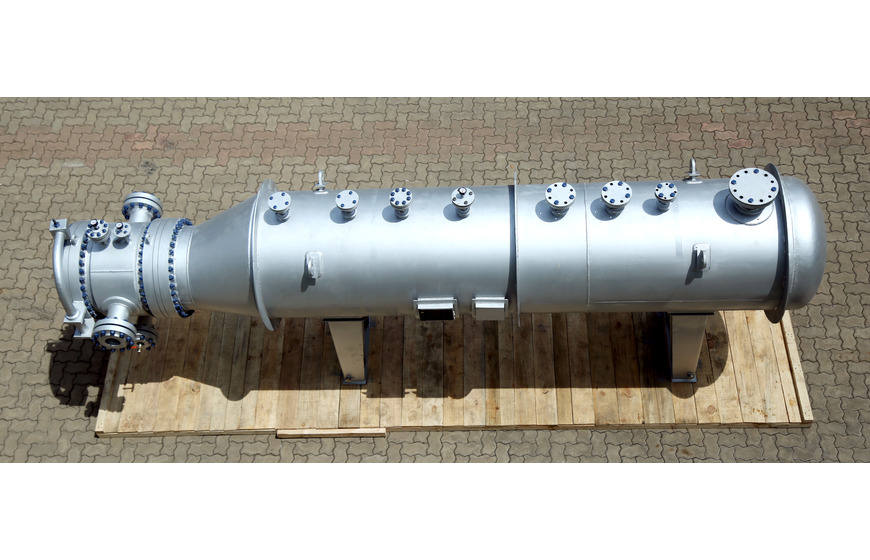

Shell and Tube Heat Exchangers

Brochure

Discover the full range of our products by downloading our comprehensive brochure today!

BROCHURE.PDF

Let’s Start Work

Together

Please feel free to contact us.

Manufacturing Unit-1 & Corporate Office

Plot No. F- 131, M.I.D.C, Ambad, Nashik- 422010.

Manufacturing Unit-2

At Post Talegaon, GAT No:352, Talegaon, Indore-Rasegaon Road, TAL- Dindori, Nashik, Maharashtra 422004

Versatile and robust, these exchangers facilitate efficient heat transfer between two fluids, widely used in industries such as HVAC, chemical processing, and power generation.

Application

- Air Processing & Compressor Cooling (Inter cooler & after cooler)

- Industrial (Fluid & Oil coolers)

- Food & Beverage

- HVAC (Air conditioning)

- Marine Applications

- Petrochemical: Processing & Refining

- Pharmaceuticals

- Power Generation

- Metals and Mining

- Refrigeration

Advantages of UHTPL Shell & Tube heat exchangers

- Good understanding of the underlying principles of exchanger.

- Capability to Diagnose for Feasibility & Viability design

- Classification of S&T HE according to construction and criticality of service

- Proper allocation of shell side and tube side fluids in S&T HE

- Decision on Baffle arrangement for tube side and shell side taking care of heat transfer and pressure drop

- Optimum Tube Lay out taking care of code requirements

- Selection of type of heat exchanger based on service which may be single phase (such as the cooling or heating of a liquid or gas) or two-phase (such as condensing or vaporizing)

- Corrosion prevention measures, when applicabl

- Fouling considerations

- Optimum design to evaluate the impact of utility and footprint constraints on the heat exchanger design

Specifications

- Optimally designed for high performance and long life using PVElite, NozzlePro and HTRI Conforming to TEMA RCB

- Material: Stainless Steel, Carbon Steel, Cupro-nickel, Copper, Brass, Gun Metal, Aluminum, Aluminum Bronze, Naval Brass, Hastealloy, Inconel, Monel, Nickel

Previous

Next