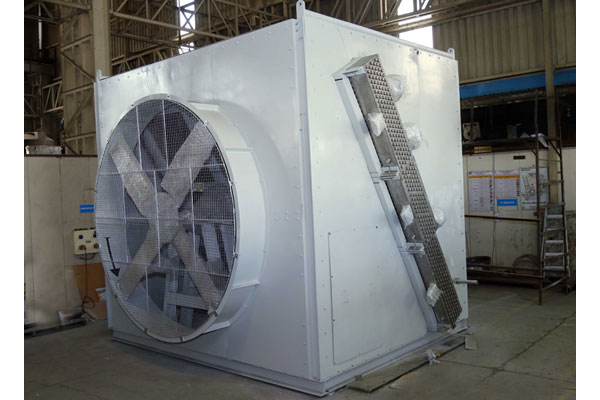

Air Cooled Heat Exchanger

In modern era, Air cooled heat exchangers are most preferred heat exchangers due to scarcity of water. UHTPL is backed up with Thermal & Mechanical Design software which guides to give optimum sized heat exchanger while taking into consideration of the ambient conditions, vibration limitations, and space constraint. Type of tube can be selected based on the temperature & pressure limitations.

Air cooled heat exchangers are mainly used in following industries

- Gas compression package

- Gas transmission facilities

- Large engine radiators

- Condensing of refrigerant gases

- Power plants, steam condensers

- Turbine lube oil cooler

- Flue gas reactors

- CNG booster compressor package

We have HTRI back-up which having library for around 10000 fluids properties essential for design of heat exchanger

Advantage of UHTPL Air cooler

- Good understanding of the underlying principles of exchanger to design on HTRI & Bentely Autopipe-Microprotal.

- Feasibility & Viability of design is verified

- Ensure effect of changing climatic conditions

- Distinguish & select type of finned tube like High-finned, low-finned, continuous-finned, stud-finned or plain tubes.

- Analysis for Heat Transfer capacity of Fin tube for cost effective heat exchanger.

- Increase efficiency of heat exchanger by considering Heat Transfer Rate, Space requirements & Air side pressure drop.

- Selection of operation of fan viz. forced draft or induced draft.

- Selection of header with respect to service requirement.

- Fan Blade Material selection depending on the area of classification

- Air Flow rate & Noise level

- Optimum power requirement

- F type Construction can also be manufactured.