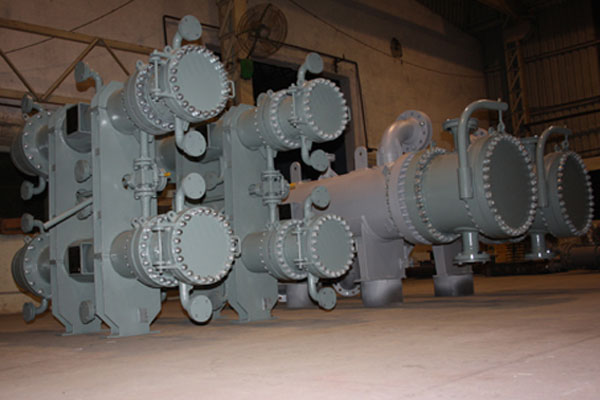

Shell And Tube Heat Exchangers

Having an experience of around 28 years with around 24000 Shell & tube heat exchangers supplied over its tenure including 1100+ heat exchangers under ASME U Certification mark, we have developed expertise in heat exchanger design & development. We are backed up by internationally reputed software like HTRI for thermal design & Bentley Auto pipe vessel for mechanical design.

Our engineering expertise gives us an cost effective solution taking care of all international standards.

We have presence in almost all variants of industries like

- Air Processing & Compressor Cooling (Inter cooler & after cooler)

- Industrial (Fluid and oil coolers)

- Food & Beverage.

- HVAC (Air conditioning)

- Marine Applications.

- Petrochemical: Processing & Refining

- Pharmaceuticals

- Power Generation

- Metals and Mining

- Refrigeration

Shell & Tube Heat Exchanger

- Good understanding of the underlying principles of exchanger to design on HTRI & Bentely Autopipe.

- Diagnosis for Feasibility & Viability design

- Classification of S&T HE according to construction and criticality of service.

- Allocation of shell side and tube side fluids in S&T HE

- Decision on Baffle arrangement for tube side and shell side heat transfer and pressure drop

- Optimum Tube Lay out taking care of code requirements

- Selection of type of heat exchanger based on service which may be single phase (such as the cooling or heating of a liquid or gas) or two-phase (such as condensing or vaporizing).

- Corrosion prevention measures

- Fouling considerations.

- Optimum design to evaluate the impact of utility and footprint constraints on the heat exchanger design

- Develop specification sheets for heat exchangers

- Terminal temperatures of fluids

Aspect Of Mechanical Design Of Shell & Tube Heat Exchanger

The principal components of Shell & Tube HX are:

- Shell

- Shell cover

- Channel

- Channel cover

- Tubes

- Tube sheet

- Baffles

- Nozzles

Other components include tie-rods and spacers; pass partition plates, impingement plate, longitudinal baffle, sealing strips, supports. The Tubular Exchanger Manufacturers Association (TEMA ) standard describes these various components in detail.

Advantages of UHTPL Shell & Tube heat exchangers

- Good understanding of the underlying principles of exchanger.

- Capability to Diagnose for Feasibility & Viability design

- Classification of S&T HE according to construction and criticality of service.

- Proper allocation of shell side and tube side fluids in S&T HE

- Decision on Baffle arrangement for tube side and shell side taking care of heat transfer and pressure drop

- Optimum Tube Lay out taking care of code requirements

- Selection of type of heat exchanger based on service which may be single phase (such as the cooling or heating of a liquid or gas) or two-phase (such as condensing or vaporizing).

- Corrosion prevention measures, when applicable

- Fouling considerations.

- Optimum design to evaluate the impact of utility and footprint constraints on the heat exchanger design